[2024] How to Replace Track Side Plate

Purpose of the Track Side Plate

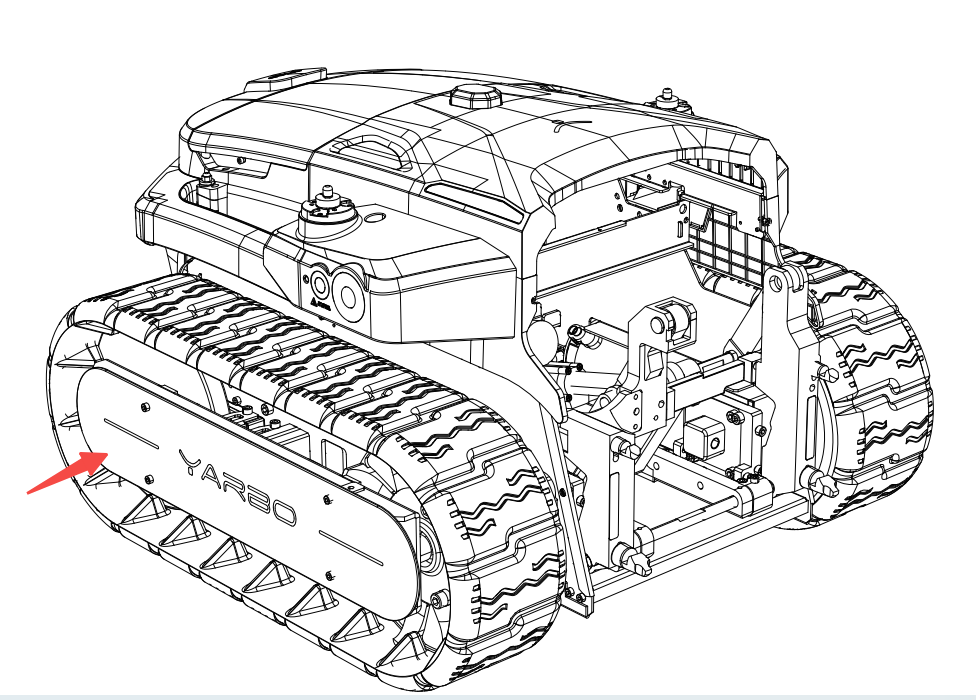

The Track Side Plate is an important component designed to prevent snow from accumulating

inside the tracks and reaching the motors, which could lead to operational malfunctions during

snow removal. Your Yarbo Core comes with two plastic-painted Track Side Plates pre-installed.

To enhance performance during snow-blowing, we recommend replacing the plastic side plates

with the more robust metal Track Side Plates when you install the Snow Blower module.

When to Replace the Track Side Plates

When you are ready to attach the Snow Blower Module to Yarbo, it’s the ideal time to replace

the Track Side Plates with the metal version. The metal Track Side Plates provide better durability

and optimal snow-blowing performance, ensuring that Yarbo continues to operate effectively

in snowy conditions.

the Track Side Plates with the metal version. The metal Track Side Plates provide better durability

and optimal snow-blowing performance, ensuring that Yarbo continues to operate effectively

in snowy conditions.

Step-by-Step Instructions for Replacement

Step 1: Gather the Tools

- You will need a Allen Key#2 that fits the screws used on the Track Side Plates.

allen key #2

- Ensure you have the replacement metal Track Side Plates ready.

Step 2: Remove the Existing Plastic Track Side Plates

- Locate the Screws: The Track Side Plate is held in place by four screws.

- Unscrew the Screws: Using your screwdriver, carefully unscrew the four screws securing the

plastic Track Side Plate. Refer to the image below for visual guidance on unscrewing the Track

Side Plates.

Step 3: Replace with Metal Track Side Plates

- Position the Metal Side Plate: Place the new metal Track Side Plate in the same position where

the plastic one was removed. - Secure with Screws: Use the same screws to securely attach the metal Track Side Plate. Make

sure the screws are tightened properly to avoid any movement during Yarbo’s operation.

Step 4: Double-Check Installation

- After securing the Track Side Plate, double-check that the screws are tight and the side plate

is positioned correctly. - This is important to prevent any potential loosening during Yarbo's work, which might affect

the machine's efficiency.

Benefits of Metal Track Side Plates

- Enhanced Protection: The metal Track Side Plates provide superior protection from snow

accumulation compared to the plastic version. - Better Durability: They are more resistant to impact and wear, making them suitable for

heavy-duty snow-clearing operations. - Improved Performance: By keeping the tracks clear of snow, the metal side plates ensure

consistent performance without interruptions due to motor clogging.

Related Articles

[2024] How to Replace Your Track to Fit the Snow

Welcome to the Yarbo Track Replacement Guide. This guide provides a step-by-step process for safely removing and replacing the tracks on your Yarbo Core. By following these instructions, you can ensure a smooth and safe replacement process without ...[2024] Refill Grease oil to the Track Regularly

1.Grease Lubrication Purchase Guideline Grease Lubrication Types: All of these three types are applicable High Vacuum Grease Recommended for applications with high vacuum conditions. Ideal for sealing and lubricating vacuum systems. Vacuum Grease ...[2024] Replace Data Center quick guide

Follow these simple steps to replace your Yarbo Data Center efficiently: In Yarbo Settings, click Replace Data Center.Notice:Your map data will be erased when you perform this action. Install Data Center according to the instructions in the User ...[2024] Yarbo Lawn Mower Maintenance Guide

Proper maintenance ensures that your Yarbo lawn mower runs smoothly and efficiently. Here’s everything you need to know to keep it in top condition. Before you start any maintenance work, please disconnect the battery first: Press the Emergency Stop ...[2024] How Does Yarbo Achieve Self-Rescue During Snow Blowing Work Plan

When using the Yarbo snow blower module in thick snow conditions, the device is equipped with an automatic track slippage recovery mode to help it overcome obstacles and continue operating effectively. How the Track Slippage Recovery Mode Works: ...